-

Secondary Battery Materials

Battery Materials Business

Conducting lithium business optimized for high nickel cathode materials

OEM sales through joint development with a single-crystal high nickel manufacturer with the best domestic technology

Secured lithium ore through overseas mining business and promoting refining business

Mixing/selling of mineral materials essential for improving the performance of cathode materials

Supply of various mixed products to domestic cathode material manufacturers

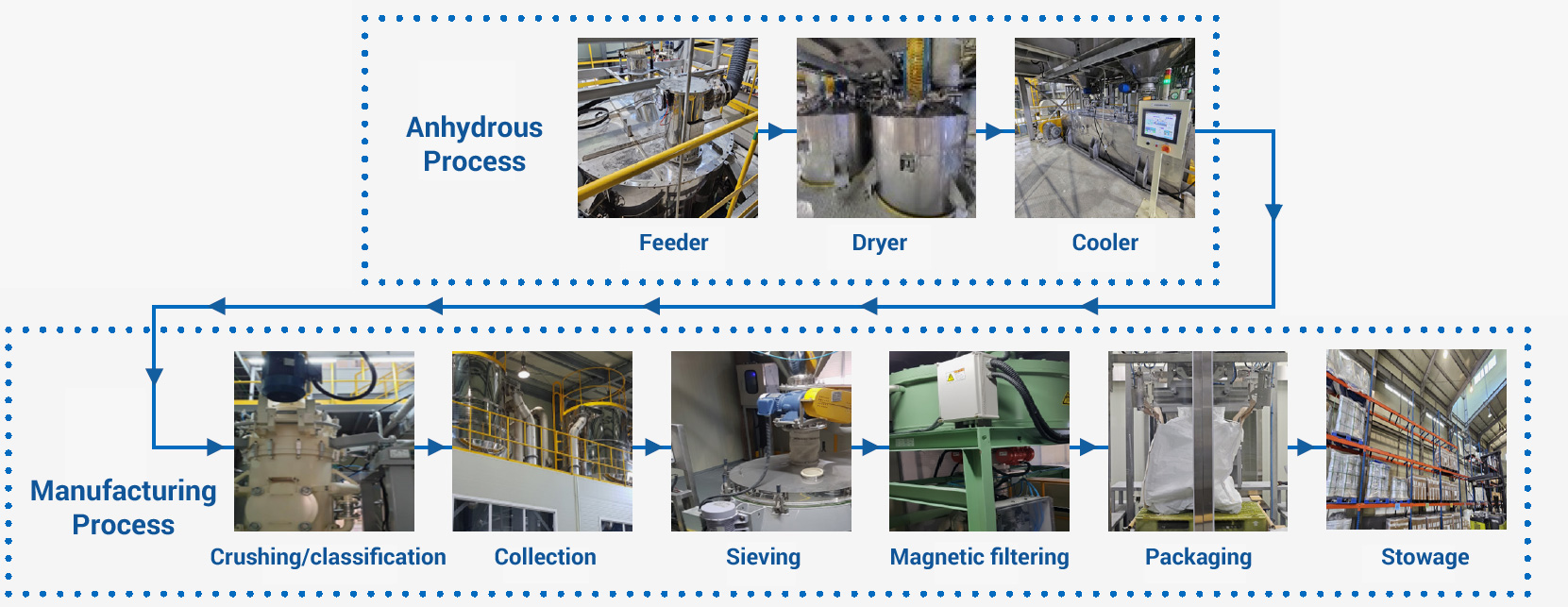

Prevents external contamination in an independent work space that is sealed and blocked from the outside

SUS#304 material ETFE inside coating

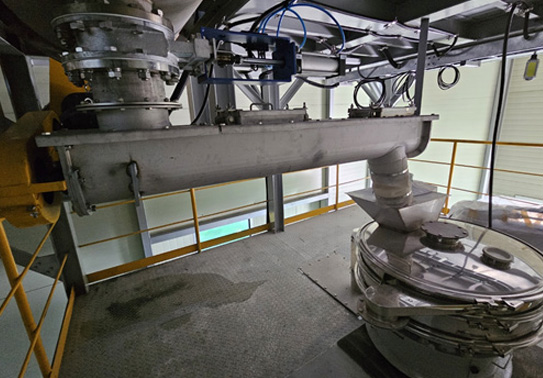

Vibrating Sieve

Permanent magnet 12,000 Gauss

Sealed packaging in 10kg aluminum pouch

Annual production capacity of 1,200 tons

Capable of varying mixing ratios according to customer requests

Block external contamination through sealing and automatic operation

All process lines use SUS316 and SUS304 materials

ETFE coating for electronic materials

Capable of responding to production in either small quantities or mass-production as per customer request

| NO | INSPECTION | SPECIFICATION |

|---|---|---|

| 1 | Dmin μm | ≥ 0.04 |

| 2 | D50 μm | 5.0±0.5 |

| 3 | Dmax μm | ≤ 20 |

| 4 | Moisture %M | ≤ 0.3 |

| 5 | Li2CO3 wt% | ≤ 2.5 |

| 6 | LiOH wt% | ≥ 97 |

| 7 | Li wt% | 30±0.5 |

| 8 | Ca ppm | ≤ 100 |

| NO | INSPECTION | SPECIFICATION |

|---|---|---|

| 9 | Cu ppm | ≤ 5 |

| 10 | Fe ppm | ≤ 5 |

| 11 | Mg ppm | ≤ 5 |

| 12 | Na ppm | ≤ 100 |

| 13 | S ppm | ≤ 100 |

| 14 | Si ppm | ≤ 3 |

| 15 | Zn ppm | ≤ 3 |

| 16 | Magnetic foreign materials ppb (Fe+Cr+Zn+Cu) | ≤ 50 |

Annual production capacity of 10,000 tons

ETFE coating for electronic materials in all process lines

Block external contamination through sealing and automatic operation

Prevents conversion to lithium carbonate by using CO2 remover

Annual production capacity of 2,000 tons

Prevents conversion to lithium carbonate by using CO2 remover

Block external contamination through sealing and automatic operation

Capable of responding to production in either small quantities or mass-production as per customer request

All process lines use SUS316 and SUS304 materials

Supplying processed lithium hydroxide specialized for electric vehicles to domestic cathode material manufacturers through business cooperation with major lithium makers

The addition of aluminum to rich nickel NCM-based materials increases output and stability; one type of aluminum and other materials are mixed, processed and added

Unique nickel-rich cathode materials are the technology that can be applied to the performance improvement of next-generation anode materials