-

Secondary Cylindrical Battery

Cylindrical Secondary Battery Business

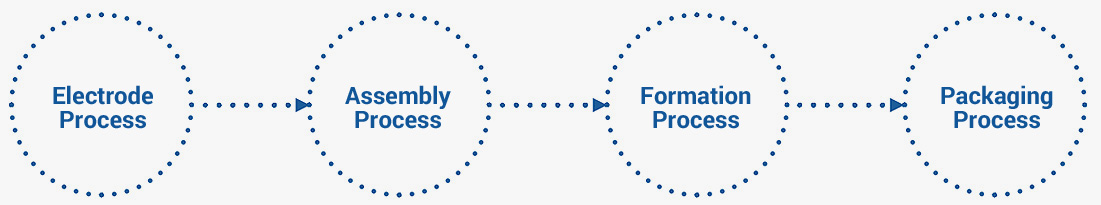

The process of making cathode and anode

High Nickel (Ni 90 or more)

Application of single-crystal cathode materials

Mixing

Coating

Roll Press

Slitting

The process involves winding the electrode, inserting it into the can, injecting electrolyte, and sealing it

Winding

JR Insert

Beading

EL Filling

Crimping

Washing

Tubing

The process involves activating the battery with electrical energy and checking its stability

RT Aging

Formation

HT Aging

DCIR

Grading

Modularization process to suit an electric vehicle model

Cell inspection and assembly

BMS assembly

EOL inspection

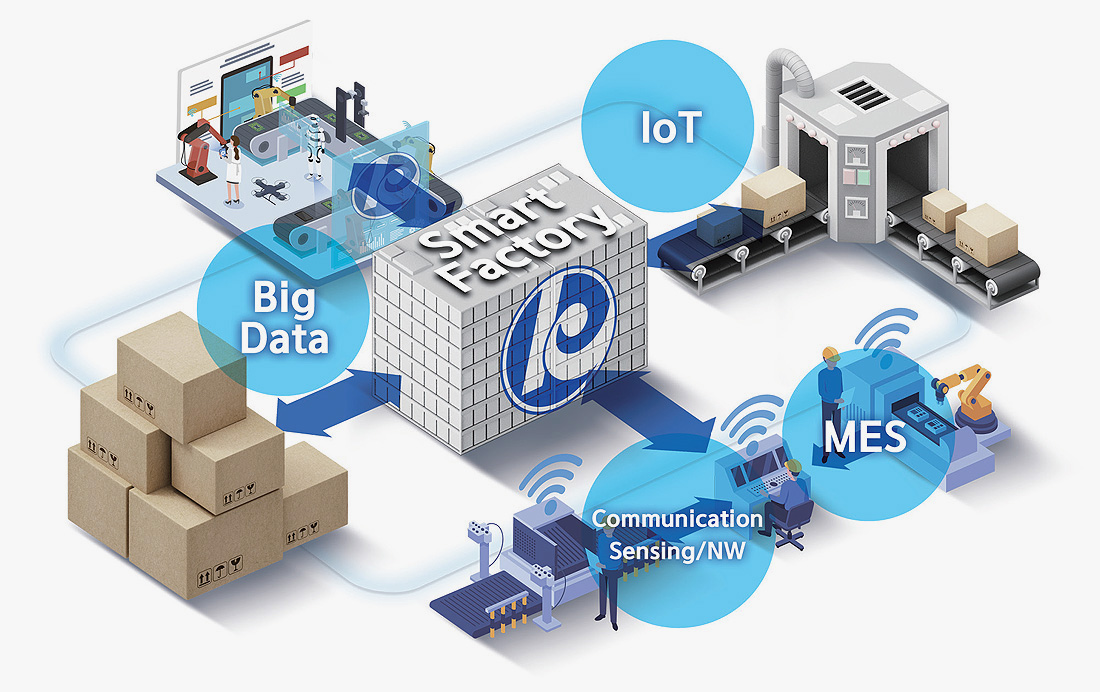

We have established an optimized smart factory to maximize facility productivity and efficiency of supply, delivery, and warehouse logistics

We have strengthened inspection by operating a deep learning process for Al-based quality monitoring

Process analysis

KPI management

Integrated control

Productivity and quality control

Predictive analysis of potential failures

Real-time integrated facility management

Electric vehicle

E-Mobility

E-motorcycle

Energy Storage System(ESS)

The 21700 battery is enhanced battery with larger capacity and higher energy density than the 18650 battery

Increased more than 50% by applying NCMA Cathode materials

Decreased costs of the number of batteries for driving single EV (Key Point: 7,000 pcs → 3,000 pcs)

Lightweight battery

Extended hours of battery use

Enhanced design for flexibility

Enhanced stability and quality of battery

| Cell Model | Capacity(mAh) | Nominal Voltage(v) | Max Continuous Discharge Current(A) | Remark |

|---|---|---|---|---|

| KY INR21700-40P | 4,000 | 3.6 | 45 | TBD |

| KY INR21700-42P | 4,200 | 3.6 | 45 | TBD |

| KY INR21700-49E | 4,900 | 3.65 | 14.7 | |

| KY INR21700-48E | 4,800 | 3.65 | 14.7 | |

| KY INR21700-50E | 5,000 | 3.65 | 15 | |

| KY INR21700-53E | 5,300 | 3.65 | 10.6 | TBD |

※ Standard size : Diameter 21mm & Height 70mm

Increase plus 5x the energy capacity more than the 21700

To increase plus 6x of power output

To extend the distance up to 16% in EV

To invest the development of cylindrical battery for meeting customer expectation

To save the cost through the technology for material and process

To be one of game changers in the global automotive industry

| Item | 21700 | 4680 |

|---|---|---|

| Diameter (mm) | 21 | 46 |

| Height (mm) | 70 | 80 |

| Weight (g) | 70 | 320 |

| Cell unit per EV | 4,400 | 960 |

| Energy capacity (mAh) | 5,000 | 25,000 |

The area of land : 180,296㎡

Gross floor area : 124,479㎡

Building area : 71,596㎡